Controlled environment module Redesign

Controlled environment module Redesign

Redesigning a Controlled Environment Module to improve user interaction

Duration: 17 weeks

Year: 2025

Execution: Graduation project

Main challenge: Improve the user experience of the controlled environment module (CEM)

Subchallenges:

Enable easier handling of the crops

Design for safe opening and closing

Increase cleanability and ease of cleaning

Improve energy efficiency by reducing energy loss

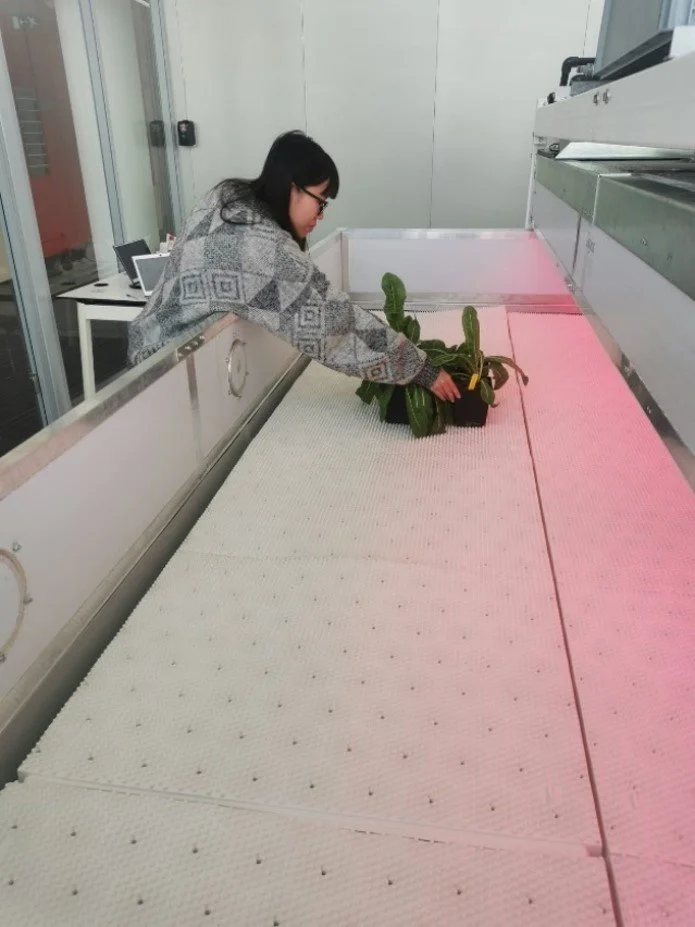

Design Challenge: Container and crop reachability

The raised edge complicates working with the crops

Current design risks damaging the tops of the crops

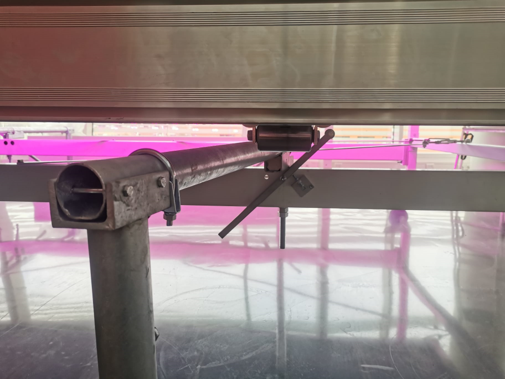

Design Challenge: Ensure safe access to the irrigation system

There is no safe climbing option to reach the irrigation system

Foldable legs are used by users as a temporary workaround

Design Challenge: Ensure easy cleaning and maintenance of the cultivation container

Challenging to access for cleaning

Walls are not designed to withstand impacts

Exposed PIR insulation and small edges or crevices present a potential hygiene risk

Design Challenge: Ensure safe operation when opening and closing the container

The electric lid presents a possible risk of entrapment

The existing rail system can lead to derailment of a fully loaded crop container

Design Challenge: Reduce energy loss

Current design results in 100 W heat loss per °C of indoor–outdoor temperature difference

A significant portion of the loss is caused by thermal bridges in the current design

The Final Design:

A comprehensive redesign of the controlled environment module that solves all the aforementioned challenges efficiently and conveniently.

Manual operation for opening and closing enhances safety

Improved crop accessibility

Minimized energy loss

Facilitated safe operation and access to the irrigation system

Enhance ease of cleaning and hygiene maintenance

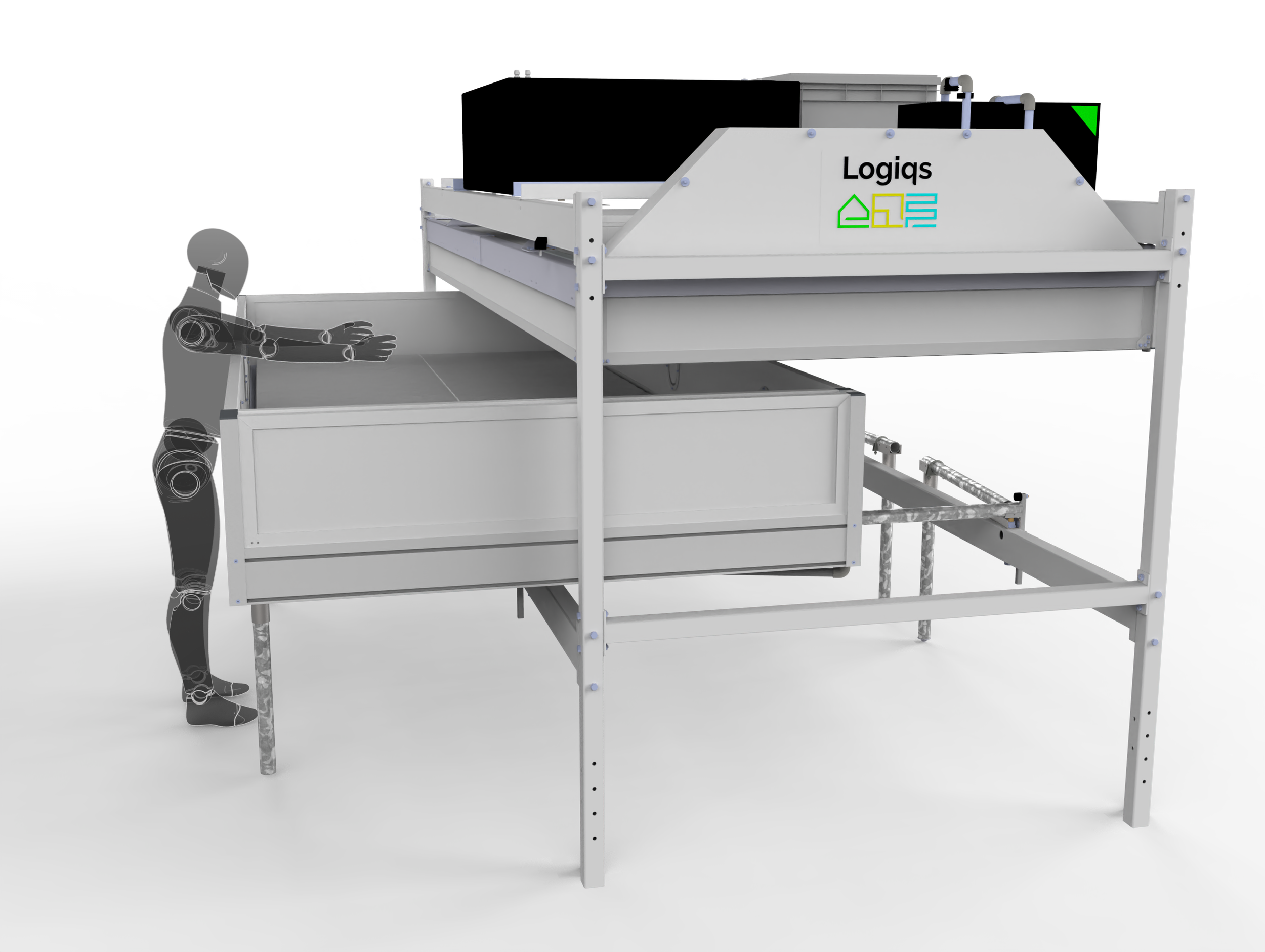

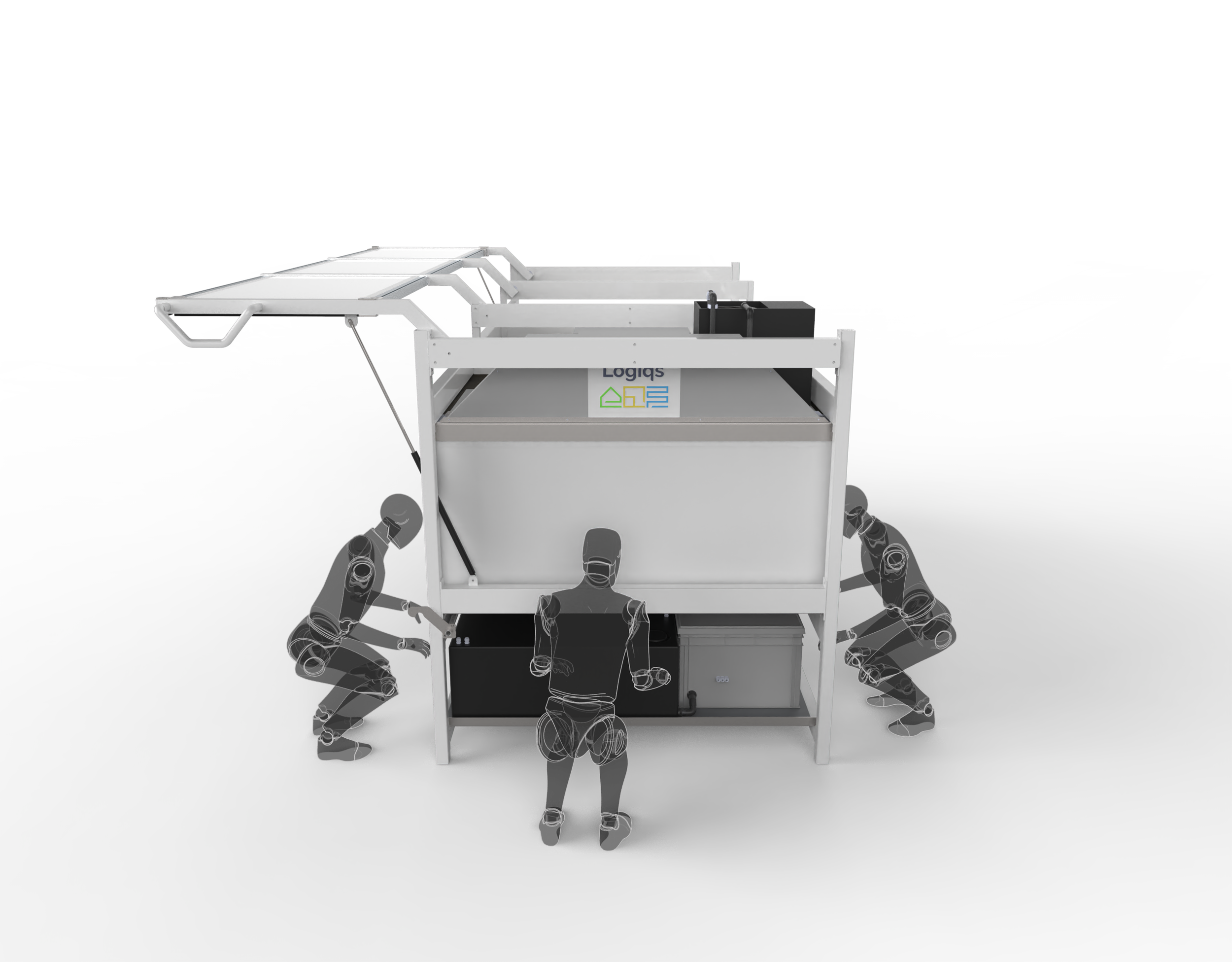

How to open the CEM?

Manual opening

Gas springs facilitate opening and support of the hatch

Designed for safe overhead clearance and accessible handle operation

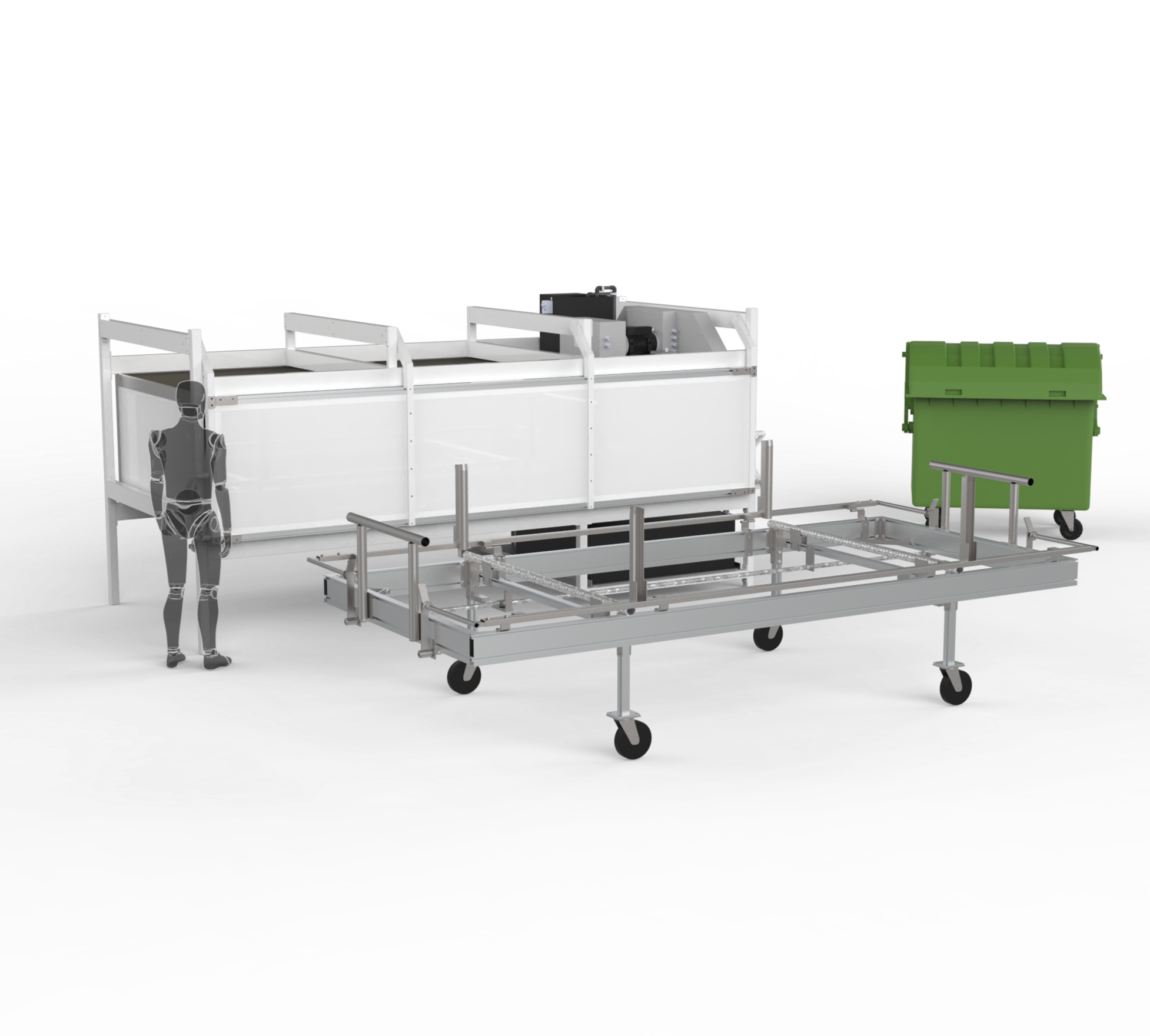

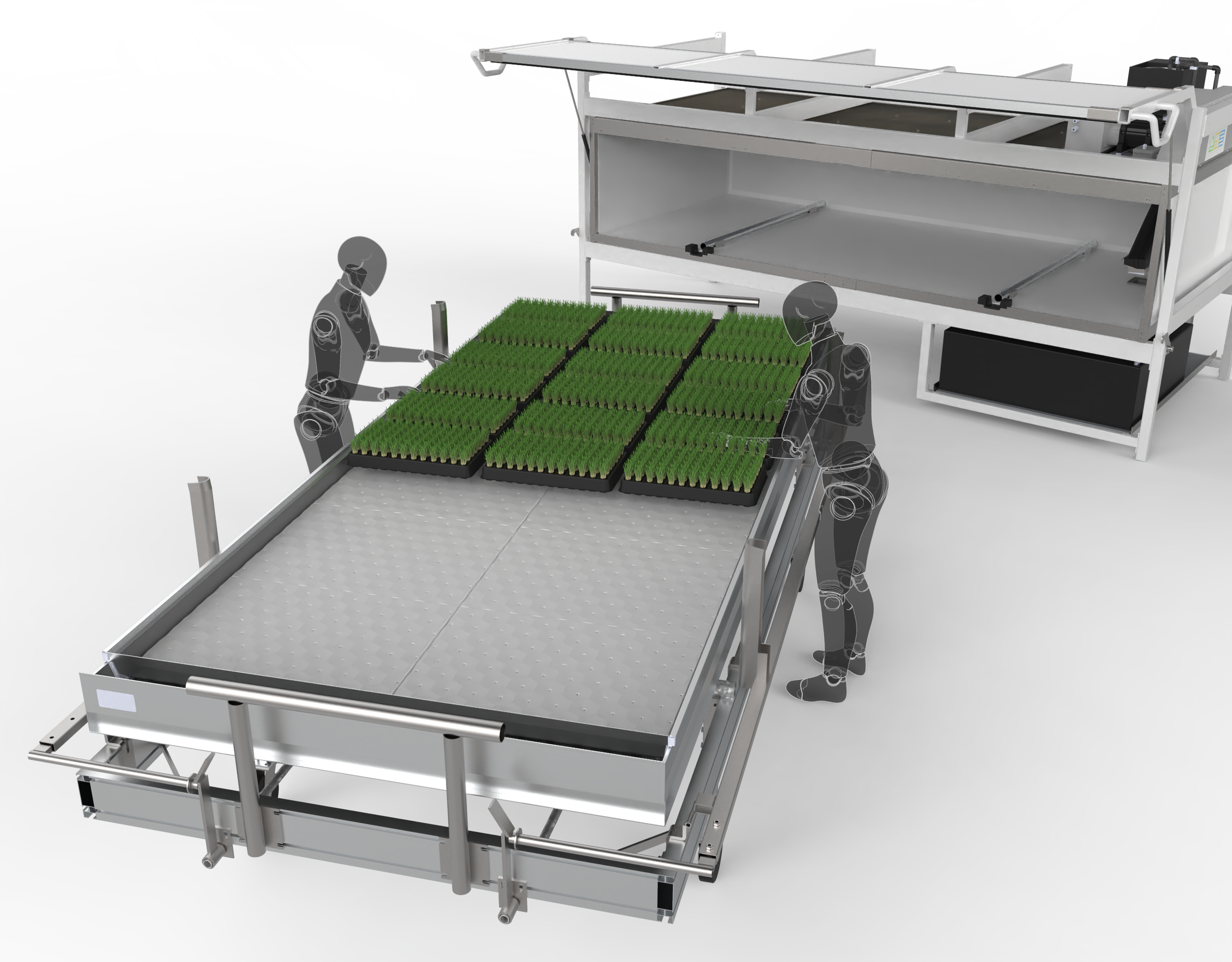

Introduction of the trolley

To allow users to work all around the container and transport crops for off-site tasks like evaluation, inspection, or disposal, a trolley has been implemented.

Relocation of the irrigation system

Facilitates access from a kneeling position

The revised position improves ease of transporting water and fertilizers by removing the need to pump dirty water upward

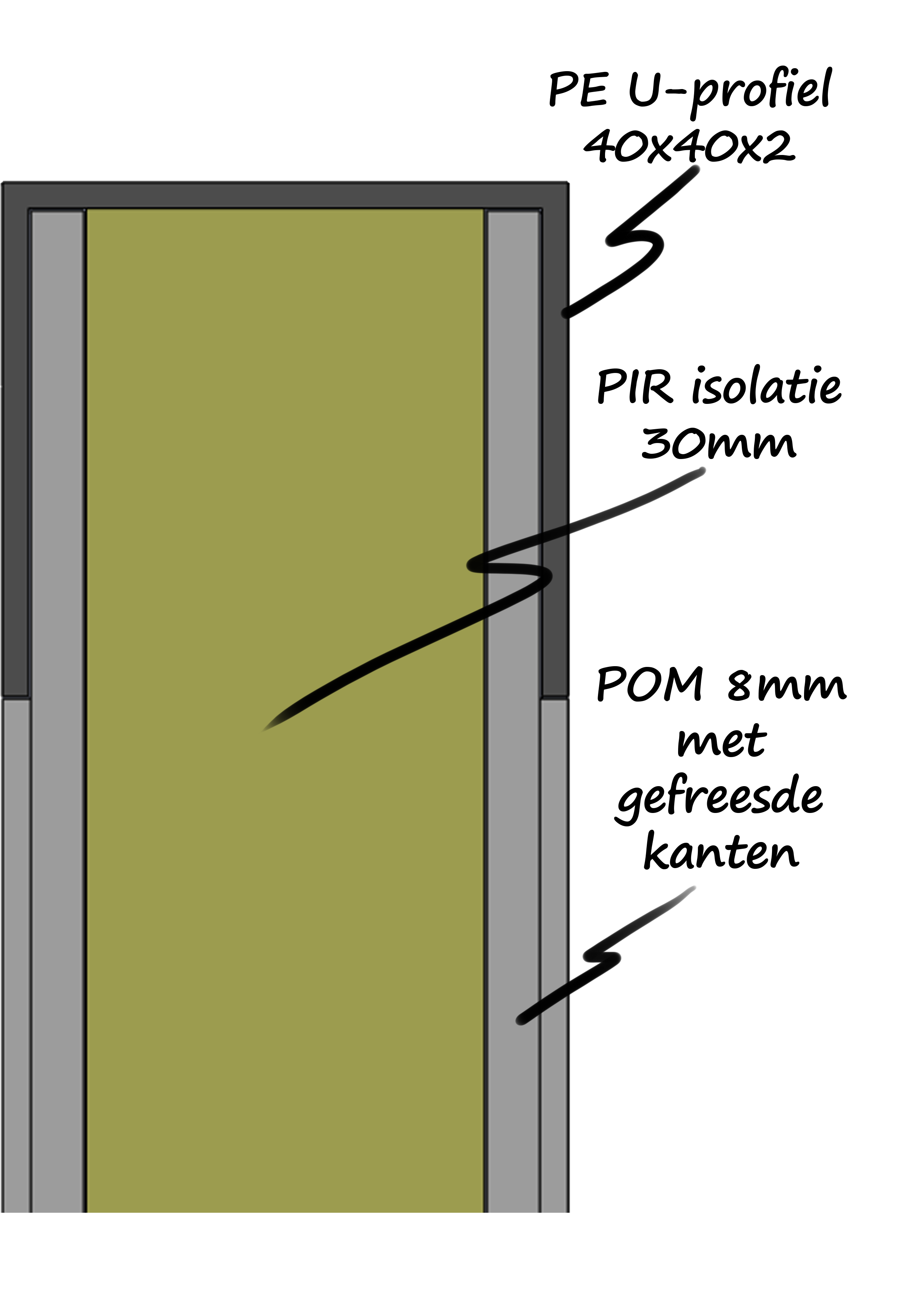

Designed for improved cleaning

The climate chamber is equipped with its own drainage, facilitating easy cleaning and rinsing.

The wall construction ensures there are no edges where dirt can accumulate and shields the insulation material from damage.

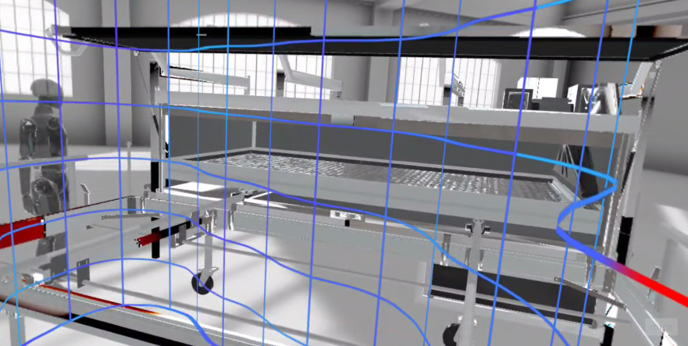

User-based verification using virtual reality

To evaluate the improvements of the new design within the limited timeframe, user tests were performed using virtual reality

Software used: